Thermodynamic Signatures and Inverse Thermal Reactions¶

1. ABSTRACT¶

Standard Model Expectation: Combustion of hydrocarbon fuels (jet fuel, office contents) follows standard thermodynamic laws ( $\(Q = mc\Delta T\)$). Fires producing high heat (incandescence) must consume available fuel (paper, wood) and cause thermal degradation of adjacent materials based on thermal conductivity ( $\(k\)$) and ignition points.

Empirical Contradiction: Forensic data reveals Inverse Thermal Reactions. "Fires" were observed that failed to burn paper or trees but melted steel and glass. Conversely, zones of "high heat" reported by bio-sensors (humans) showed no visible flame, while other zones showed visible "flames" that were cool to the touch or failed to boil water.

Audit Objective: To evaluate whether the observed thermal phenomena are consistent with chemical combustion ( $\(\Delta H_{comb}\)$) or if they indicate non-thermal electromagnetic heating (interferometric/RF coupling and dielectric heating).

2. CONTROL PARAMETERS¶

Thermodynamic System Definition:¶

We treat the Debris Field as a Radiant Heat Transfer problem.

- Radiant Flux Constraint ($\(Q_{rad}\)$):

$$Q_{rad} = \epsilon \sigma (T_{source}^4 - T_{target}^4) F_{view} $$

The "Heat Flux Contradiction" (The Exclusionary Rule):¶

- Standard Model Requirement: To melt steel or aluminum ($\(T > 600-1500^\circ\text{C}\)$ ) via an external fire, the surrounding Radiant Heat Flux ($\(Q_{rad}\)$ ) typically requires high incident flux (often tens of kW/m², depending on view factor, duration, shielding, airflow, and target geometry).

- Exclusion logic: At flux levels in this range, exposed low-mass combustibles (paper/leaves/plastics) are generally expected to pyrolyze/ignite on short timescales (seconds to tens of seconds, moisture/orientation dependent) unless effectively shielded or cooled.

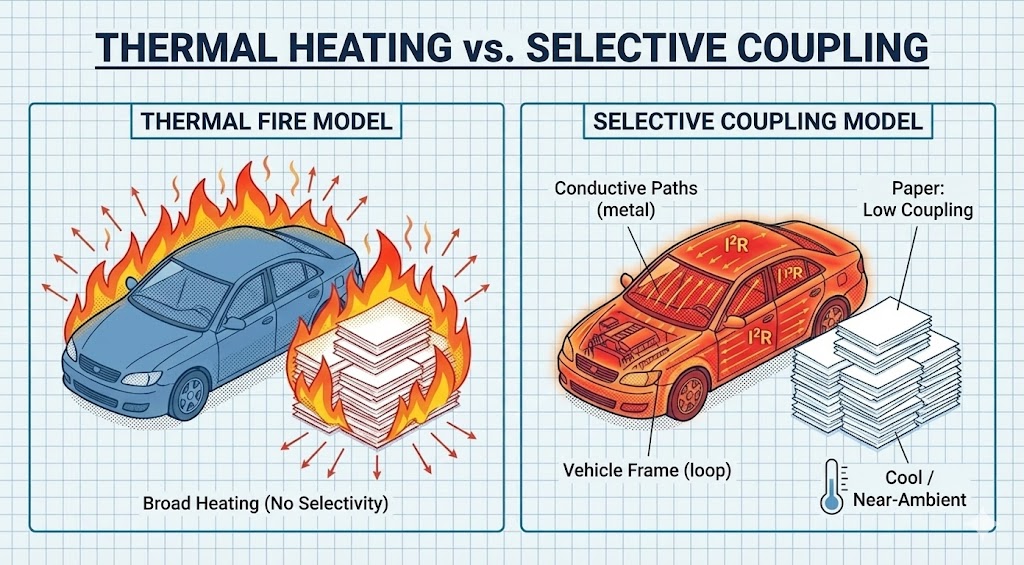

- Constraint: If severely altered metal is documented adjacent to intact paper/plastics without demonstrated shielding/oxygen starvation, a purely external thermal-radiative/convective pathway becomes less consistent, motivating a conductor-selective internal heating pathway as a competing explanation.

- Required Mechanism (mechanism class): conductor-selective internal power deposition (CLC default where loops exist; downstream eddy-current/Joule heating $\(P=I2RP=I^2RP=I2R\)$; SIH phenotype where claimed) and/or non-incandescent luminosity mechanisms.

Phase Change Energetics (Steam):

- Water expands 1600:1 when flashing to steam at $\(100^\circ\text{C}\)$ .

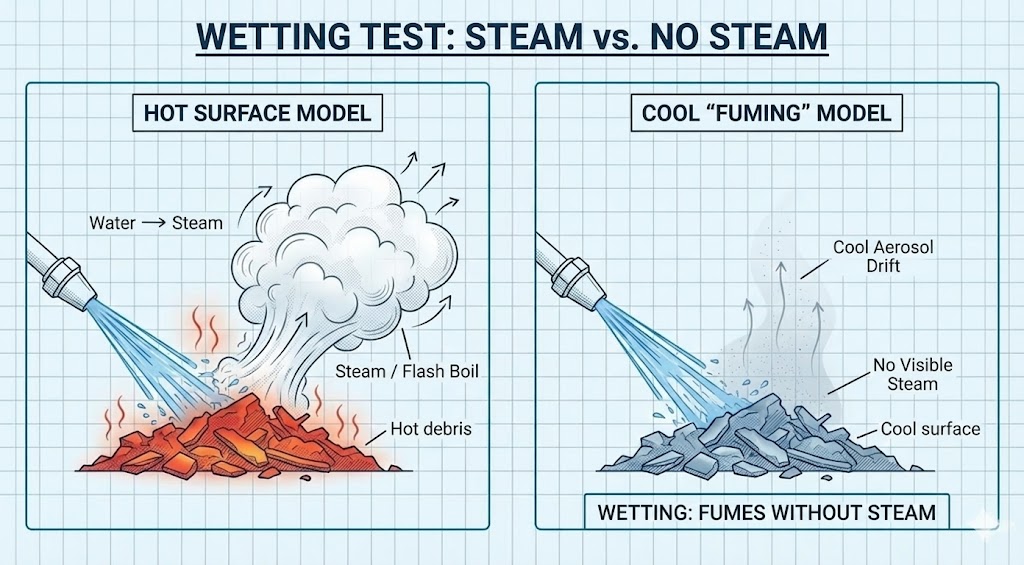

- Constraint: A debris pile containing molten metal ($\(T > 1500^\circ\text{C}\)$ ) must generate explosive steam venting when saturated with water. If liquid water contacts extensive surfaces that are ($\(\gtrsim 100^\circ C\)$ ), steaming/flash boiling is expected. Persistent absence of steaming under active wetting is therefore consistent with cooler near-surface conditions or poor wetting/insulation/venting effects; it is an audit discriminator only when water contact is documented.

3. DATA CURATION & ANALYSIS¶

EVIDENCE FILE A: Selective Impedance Heating (Paper vs. Steel)¶

- Visual Data: Images show unburned paper, flags, and leafy trees sitting directly adjacent to "raging fires" and buildings undergoing total structural failure. Specific instances show vehicles with selectively oxidized interiors or engine blocks while nearby paper debris remains white and unburnt. A minivan is consumed by flames while the paper-covered ground around it is untouched.

- The Standard Model Defense: "Oxygen starvation" or "Wind currents."

- Boundary Condition Violation:

- The Flux Paradox: To melt steel, the local Radiant Flux must exceed $\(50 \text{ kW/m}^2\)$. This flux level would generally be expected to pyrolyze/ignite exposed paper unless shielding/cooling is demonstrated.

- Observation: The dielectric (paper) survived; the conductor (steel) failed.

- Vector Analysis: This violates the Radiant Flux Constraint. The survival of the paper functions as a constraint: the dominant energy deposition did not couple broadly into adjacent low-loss dielectrics but localized preferentially in conductors (steel/cars), supporting conductor-selective coupling in conductive networks (CLC default where loops exist, downstream I²R (Joule) heating; SIH phenotype where claimed) rather than uniform external heating.

- Classification: Selective Impedance Heating / Interferometric Side-Lobe Radiation (CLC as default conductor routing; SIH phenotype where claimed).

EVIDENCE FILE B: The "Cool Fire" Phenomenon¶

- Visual Data: Rescue workers are observed walking through and standing on debris piles exhibiting Athermal Aerosol Emission. Water sprayed onto these "smoking" zones fails to produce steam explosions. Bio-telemetry confirms workers did not suffer thermal burns despite being in zones reported as "hot spots." Oxy-fuel torch hoses lie draped across the rubble without melting or exploding.

- The Standard Model Defense: "Deep-seated fires with surface cooling."

- Boundary Condition Violation:

- Phase Change Failure: If large areas of the rubble surface were persistently at very high temperature and were actively wetted, significant steaming/flash boiling would be expected. Reported ‘fuming’ with limited steaming under wetting is treated here as more compatible with cool-to-warm aerosol emission than with broad open-flame combustion at the surface.

- Mechanism: The ‘fumes’ are carried here as non-combustion aerosol emission (IMD athermal-ionic mode) within the SCIE stack, with particle composition/morphology serving as the audit discriminator (mineral/metal particulate vs soot-dominant smoke).

- Classification: IMD (athermal ionic mode) / Athermal Aerosol Emission.

EVIDENCE FILE C: Hydraulic System Survival¶

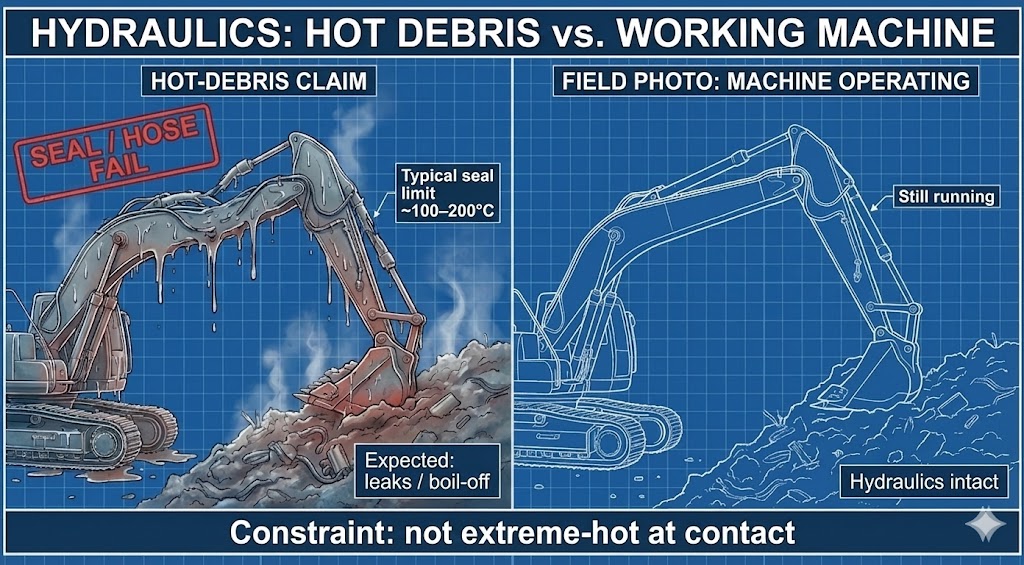

- Visual Data: Heavy machinery (grapplers) is shown digging into piles exhibiting Athermal Aerosol Emission. The hydraulic cylinders and lines are in direct contact with debris purported to be "molten" or extremely hot.

- The Standard Model Defense: "High-temperature equipment rating."

- Boundary Condition Violation:

- Seal Failure Limit: Many common elastomer seals/hoses degrade in the $\(~100–200°C\)$range depending on material and duty cycle. Continued close-contact operation is therefore treated as in tension with claims of sustained very high near-surface temperatures, unless shielding/stand-off/contact time explains survival.

- Thermodynamic Limit: Digging into $\(>600^\circ\text{C}\)$ debris would cause immediate catastrophic seal failure and fluid boiling.

- Observation: The continued operation of this equipment confirms the bulk debris field temperature was $\(< 135^\circ\text{C}\)$, contradicting reports of "molten steel" at the surface.

- Classification: Low-Temperature Material State / False Telemetry.

EVIDENCE FILE D: Anomalous Luminosity (Glowing without Heat)¶

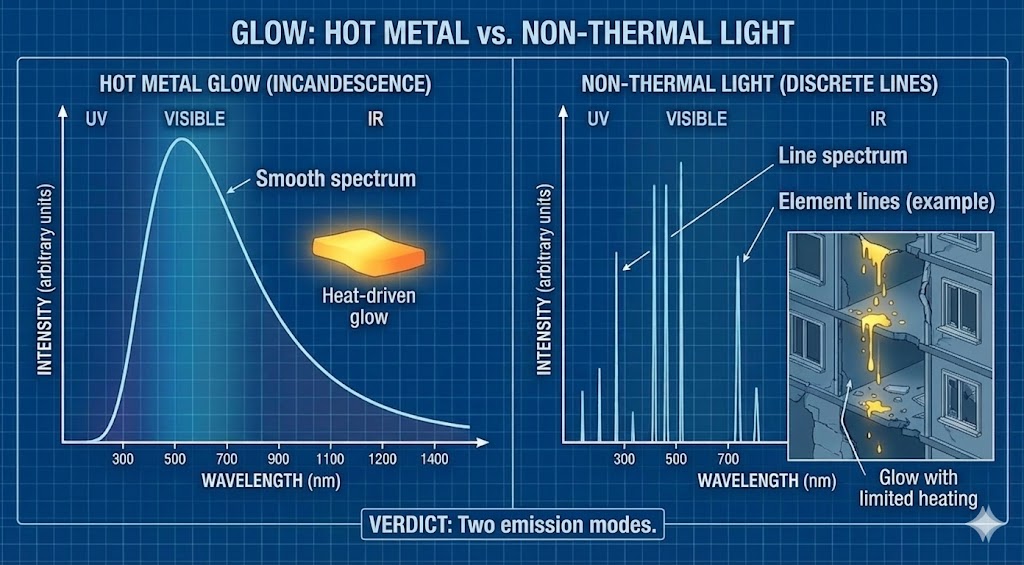

- Visual Data: Material dripping from WTC2 (80th floor) glows yellow-orange. Aluminum cladding and other debris on the ground also exhibit a glow. However, adjacent materials do not burn, and the flowing material maintains its color consistency during freefall, which is inconsistent with rapid cooling of molten metal.

- The Standard Model Defense: "Molten steel or aluminum mixed with organics."

- Boundary Condition Violation:

- Co lor Temperature Mismatch: Incandescent yellow/orange appearance corresponds to high radiance temperatures (order-of-magnitude $\(~( \gtrsim 900–1100^\circ C)\)$, emissivity dependent). If such luminosity is asserted without commensurate collateral ignition/heating signatures in nearby materials, this motivates non-incandescent luminosity (electroluminescence / non-equilibrium emission) as a candidate class rather than ordinary bulk incandescence alone.

- Classification: Non-incandescent luminosity (electroluminescence / non-equilibrium emission), with spectral/photometric discrimination as the audit discriminator.

4. CORROBORATING BIO-TELEMETRY & SENSORY DATA¶

- Objective: Cross-reference physical anomalies with independent human sensory inputs acting as biological transducers.

DATA SET A: Inverse Thermal Sensation (Hot but Cool)¶

Node-Interior Vector [ID: RM-01 | Calibration: Fire Suppression Specialist]¶

- Input Data: Subject traversed a zone of zero-visibility particulate density ("pitch black") purported to be a fire zone.

- Observation Specifics: Dermal and respiratory sensors registered the medium as "cool air" ( $\(T \approx T_{ambient}\)$) despite the visual appearance of smoke/dust.

- Boundary Condition: The presence of breathable, athermal "smoke" is inconsistent with a hot combustion smoke plume at the point of exposure, and functions as a constraint favoring cool particulate aerosol over hot-gas smoke.

Node-Perimeter [ID: AR-02 | Calibration: Fire Suppression Specialist]¶

- Input Data: Subject applied aqueous suppression agents to visible vehicle "fires."

- Observation Specifics: Application of water ( $\(H_2O\)$) produced zero thermodynamic phase change (no steam generation) and failed to arrest the oxidation process.

- Mechanism Match: Consistent with conductive-loop coupling (CLC), where the energy source is internal to the metal chassis (downstream I²R heating), rendering surface cooling ineffective.

CROSS-CALIBRATION [Network Mapping]:¶

The telemetry from [ID: RM-01] and [ID: AR-02] triangulates Evidence File B, confirming the Athermal nature of the "smoke" and the Non-Combustion nature of the "fires."

DATA SET B: Induced Thermal Perception (Cool but Hot)¶

Node-Upper Strata [ID: MD-03 | Calibration: Civilian Occupant (911 Telemetry)]¶

- Input Data: Subject reported extreme thermal load ("burning up") while simultaneously confirming the absence of visible flame ("no fire").

- Observation Specifics: Reported thermal perception without an accompanying flame front is treated here as potentially compatible with a field-mediated heating pathway distinct from surface convection.

- Mechanism Match: Dielectric heating in water-rich tissue can scale with field frequency and loss (order-of-magnitude ($\(\propto \omega \epsilon'' E^2)\)$). This is carried as a candidate mechanism only; quantitative confirmation would require instrumented dosimetry and environmental constraints.

Node-Remote Vector [ID: RO-04 | Calibration: Emergency Medical Technician]¶

- Input Data: Subject located 0.75 miles from epicenter reported sensation of "intense heat" without clear local flame contact.

- Observation Specifics: A reported heat sensation at distance without an evident convective transport pathway is treated as compatible with side-lobe / remote exposure only as a candidate interpretation.

CROSS-CALIBRATION [Network Mapping]:¶

Telemetry from [ID: MD-03] and [ID: RO-04] is carried as supportive of a non-flame heating claim only to the extent it is corroborated by independent measurements (RF anomalies, instrumented temperature/flux, or documented environmental conditions) rather than sensation reports alone.

DATA SET C: Visual/Physical Disconnect¶

Node-Ground Zero [ID: JC-05 | Calibration: Fire Suppression Specialist]¶

- Input Data: Recovery of biological remains exhibiting anomalous damage patterns.

- Observation Specifics: Subject observed total carbonization of biological tissue ("burnt to a crisp") while the adjacent dielectric covering (clothing) remained intact.

- Mechanism Match: A reported mismatch between tissue damage and adjacent clothing integrity is treated as a candidate selective-coupling phenotype only if corroborated by medical/forensic documentation and alternative pathways (flashover, contact burns, accelerants, post-event effects) are excluded.

CROSS-CALIBRATION [Network Mapping]:¶

The telemetry from [ID: JC-05] corroborates Evidence File A (Selective Heating of Conductors), validating the SCIE model of impedance-based targeting.

5. MECHANISMS OF NON-THERMAL FAILURE (Summary)¶

- Phenomenon: Paper surviving next to burning cars $\(\rightarrow\)$ Mechanism: Selective Impedance Heating (CLC / interferometric side-lobes; SIH phenotype where claimed)

- Phenomenon: Water failing to turn to steam on "hot" debris $\(\rightarrow\)$ Mechanism: IMD (athermal ionic mode) (Cool Fumes)

- Phenomenon: Glowing material that doesn't burn adjacent items $\(\rightarrow\)$ Mechanism: Non-Equilibrium Plasma / Electroluminescence

- Phenomenon: Humans feeling heat without fire $\(\rightarrow\)$ Mechanism: Dielectric Heating / Microwave Effect

6. MICROSCOPY PROTOCOL¶

Objective: Distinguish Combustion from conductor-selective coupling / IMD effects (CLC default where loops exist; IMD where bond-level dissociation is implied)

TEST A: Cellulose Fiber Analysis (Unburnt Paper)¶

- Sample: Paper recovered adjacent to "toasted" cars.

- Standard Prediction: Thermal Degradation. Fibers should show browning, charring, or embrittlement (pyrolysis) even if not fully consumed.

- SCIE Prediction: Pristine Lattice. Fibers should show zero thermal stress. However, if the field was intense, we might see Dielectric Breakdown tracking (micro-lightning scars) on the paper surface without thermal charring.

TEST B: Metal Oxide Morphology¶

- Sample: The "Toasted" car paint/metal interface.

- Standard Prediction: Layered Oxidation. Paint burns off, then metal oxidizes from the outside in.

- SCIE Prediction: Explosive Delamination. The metal surface should show signs of rapid heating beneath the paint, blowing the paint off mechanically via rapid subsurface heating/expansion and interface failure, with a steep near-surface heat-affected gradient consistent with fast internal power deposition. The metal grains should show Skin Effect (surface recrystallization) while the core remains cold-rolled.

7. SYNTHESIS: The SCIE Classification Protocol¶

- Thermodynamic Gap: The Standard Model fails to account for the Inverse Thermal Reactions. High heat ( $\(>1000^{\circ}C\)$) cannot exist alongside unburnt paper and cool-to-the-touch "smoke" without violating the laws of thermal equilibrium. The energy required to melt steel while leaving paper intact is carried as a material-selective heating phenotype that is difficult to reconcile with uniform thermal exposure/near-equilibrium heat transfer without additional shielding/decoupling assumptions.

- Circuit Gap: The specific targeting of conductive materials (steel, human bodies via water content) while sparing dielectrics (paper, clothing, rubber hoses) motivates coupling via impedance / dielectric loss (CLC as default for conductive loops and networks; dielectric heating for water-rich tissue) rather than a purely convective flame-front account.

- The Classification:

- Rule A (Attributes): The event is defined by:

- Selective Coupling: Conductors (steel) and high-dielectric loss materials (water) heated; low-loss dielectrics (paper) spared.

- Geometric Flux Constraint: "Fires" and heating effects were localized and seemingly spontaneous (as reported by Connolly and Ruiz).

- Systemic Circuit Integration: The correlation of "cool" Athermal Aerosol Emission with "hot" inductive heating signatures across a wide area.

- Rule B (Justification): Within the mechanism classes evaluated in this dossier, a SCIE-class explanation (Spatially-Constrained Interferometric Event) is favored because it satisfies the cited boundary conditions (selective heating, athermal aerosol emission where claimed, and distance-independent thermal perception reports) with fewer missing collateral signatures than a combustion-only account under the stated assumptions.