IMD/ECR Signatures and Oxidation Kinetics in Structural Steel¶

1. ABSTRACT¶

Standard Model Expectation: In a gravity-driven collapse ($\(U_g=mgh\)$ ) and/or compartment-scale hydrocarbon fires (order-of-magnitude hundreds to ~1000°C locally, time- and ventilation-dependent), structural steel (A36 wide-flange beams) is expected to exhibit ductility/buckling, plastic hinge formation, and/or fracture consistent with mechanical overload and thermal softening. Oxidation is ordinarily surface-limited and its apparent “growth” reflects oxygen uptake (oxide formation) rather than disappearance without byproducts.

Empirical Contradiction: Forensic photography—cited in FEMA Appendix C—documents severe localized section loss (laminar thinning/exfoliation), voiding/porosity features, and reported accelerated oxidation kinetics post-recovery. These phenotypes are treated here as inconsistent with a simple uniform fire/collapse exposure without additional localized driving conditions.

Audit Objective: To evaluate whether standard thermal (fire) or kinetic (impact) energy budgets can account for the observed morphological changes (microstructural porosity and severe cross-sectional area reduction).

2. CONTROL PARAMETERS¶

Thermodynamic System Definition:¶

We treat the steel degradation as a mass-balance audit over a defined control volume (member + immediate surroundings).

Audit identity (mass balance):

$$(m_{0} \approx m_{remaining} + m_{oxide;formed} + m_{exported}) $$ $$\text{exported} = \text{aerosol/scale/spall/slag/removed fragments} $$

The audit discriminator is whether the observed section loss is accompanied by commensurate, observable byproducts (oxide/scale/slag/particulate deposition) at the appropriate scale.

The "Dry Erosion" Paradox:

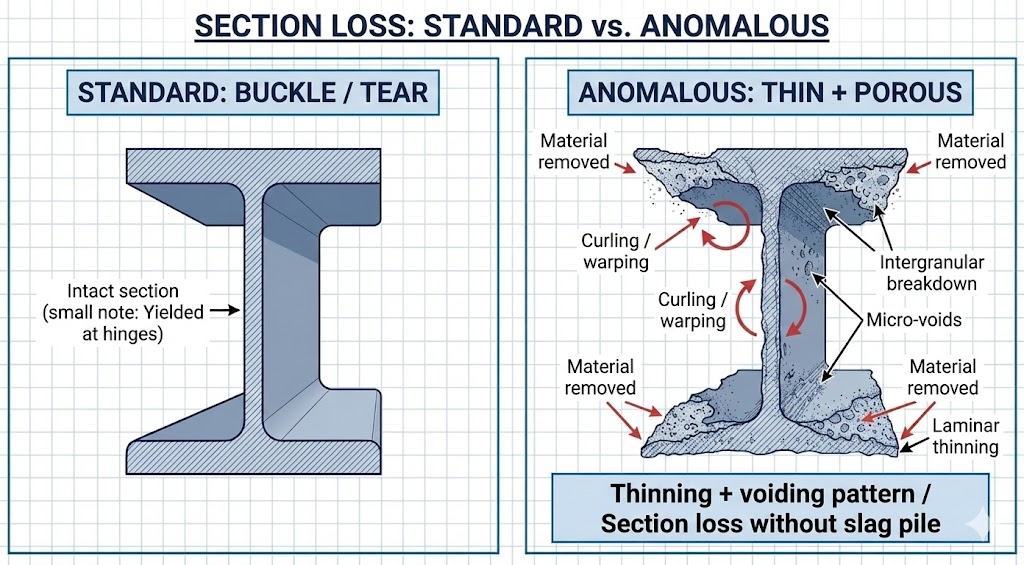

- Standard Model (Oxidation/Corrosion): Metal turns to oxide. Mass is added (Oxygen). Volume expands (Rust is less dense than Steel).

- Standard Model (Melting/Sulfidation): Metal turns to liquid. Mass is conserved but displaced (Dripping/Slag).

- Observation (Laminar Exfoliation): Steel members exhibit Extreme Section Loss (Paper-thin flanges) with No Visible Slag Pile and No Volumetric Oxide Expansion. The material is simply gone.

- Constraint: If substantial apparent section loss is asserted and no commensurate local byproduct inventory is documented (oxide/scale/spall/slag/particulate accumulation consistent with the missing mass), then a simple "surface corrosion" or "bulk melt/drip" account is under-supported. This functions as a boundary condition supporting field-mediated removal/transport (rapid macroscopic aerosolization / particulate export), with byproduct accounting and microscopy serving as the audit discriminator.

Kinetics Regime Check:

- Standard Atmospheric Corrosion: Linear/Logarithmic. Slow ($\(< 0.1 \text{ mm/year}\)$).

- Standard High-T Oxidation: Parabolic ($\(w^2 = k_p t\)$). Requires protective scale.

- The Anomaly: Reported rapid section loss/penetration on short timescales combined with strong selectivity (one member heavily affected while adjacent members are comparatively intact) is difficult to reconcile with ordinary atmospheric corrosion kinetics under broadly similar exposure. This pattern motivates a localized driving condition (chemistry, temperature history, electrical/field effects, or contamination) beyond simple ambient rusting, but attribution requires controlled context (wetting/salts/cleaners, thermal history, coating condition, and contact couples).

3. DATA CURATION & ANALYSIS¶

EVIDENCE FILE A: Laminar Thinning and Micro-Void Formation¶

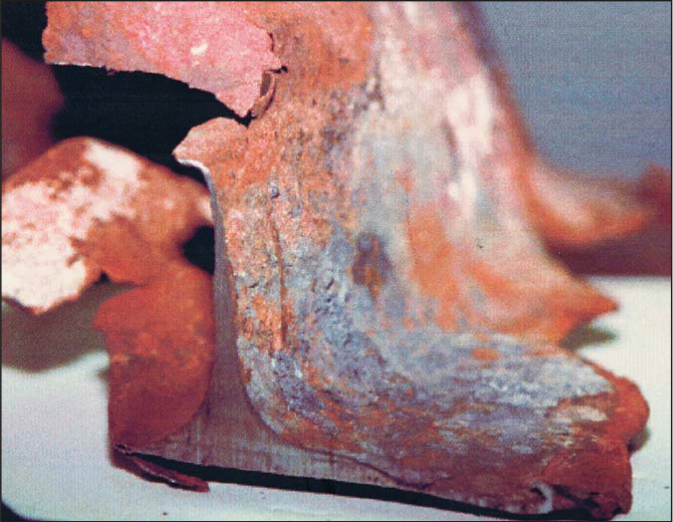

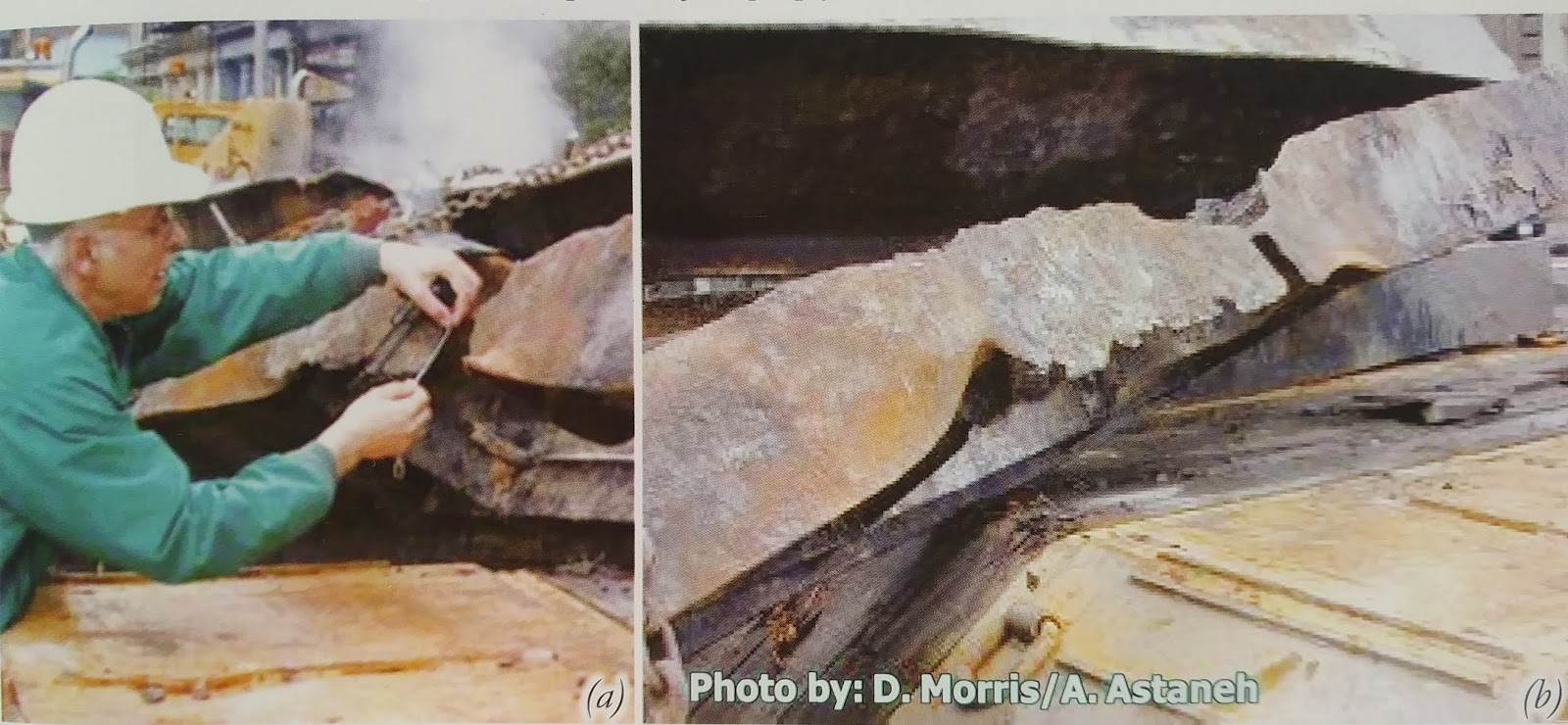

- Visual Data: Wide-flange steel beams (WTC7 and WTC1/2 samples) display extreme erosion. Flanges are thinned to millimetric thickness and curled, exhibiting Laminar Exfoliation. "Anomalous Porosity" penetrates the steel. The erosion boundary is sharp; adjacent steel appears relatively intact.

- The Standard Model Defense: "High-temperature Sulfidation" (FEMA Appendix C) or "Mechanical Abrasion."

- Boundary Condition Violation:

- The Eutectic Trap: Sulfidation requires a liquid phase (eutectic slag). The beams appear "dried out" and eroded, with no slag pile.

- The Mechanical Trap: Abrasion removes material but cannot create Internal Voids deep inside the metal lattice while leaving the remaining mesh thin and curled without brittle fracture.

- Conclusion: The combination of severe localized section loss with curled/ductile remnants is not well-explained by brittle fracture alone, and a simple “bulk melt/drip” account would ordinarily be expected to leave clearer flow/slag signatures. This phenotype functions as a boundary condition supporting a localized, non-uniform energy/chemistry coupling pathway.

- Classification: IMD / ECR-regime conductive coupling (SCIE stack label), with microscopy used to discriminate bulk thermal flow from bond-level decohesion/removal mechanisms.

EVIDENCE FILE B: Hyper-Accelerated & Latent Oxidation¶

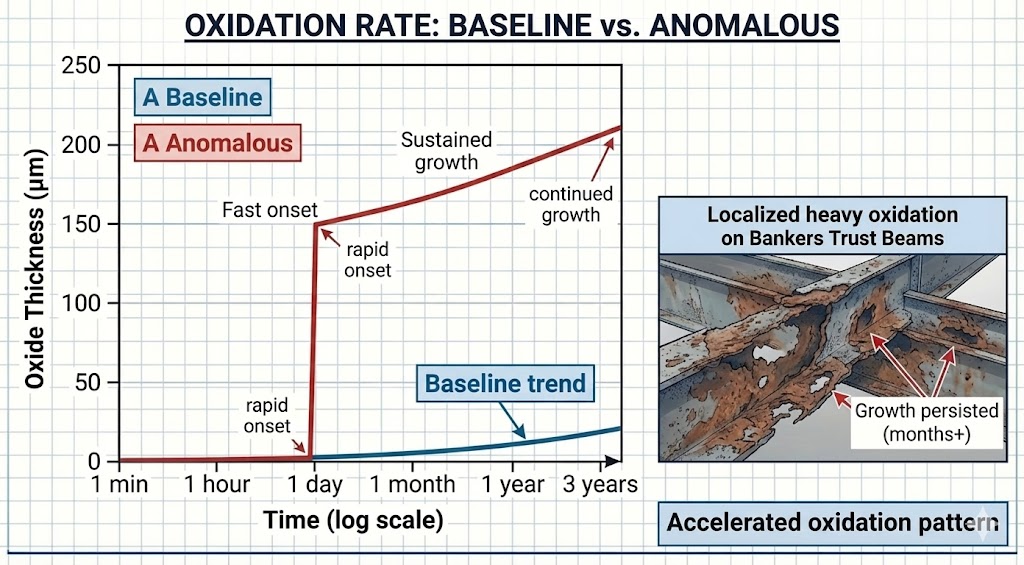

- Visual Data: Steel pipes and beams transitioned to bright orange, granular oxide immediately (days) after exposure. The oxidation was nonuniform (Anomalous Oxide Propagation), attacking specific members while adjacent ones remained relatively pristine. Crucially, reports describe unusually heavy oxide growth on certain members on timescales presented as short relative to ordinary sheltered indoor corrosion. If verified, such growth would be inconsistent with standard passivation-limited kinetics absent strong accelerants (persistent wetting, salts/cleaners, galvanic couples, microbiological activity, coating removal, or unusual surface condition).

- The Standard Model Defense: "Rainwater/Salt/Fire Hose exposure."

- Boundary Condition Violation:

- Provenance Check: The Bankers Trust beams were internal, shielded from direct weather.

- The Selectivity Paradox: "One beam rusted, adjacent one clean" violates the "Uniform Environment" assumption of atmospheric corrosion.

- Non-Self-Quenching: Standard oxidation forms a passivation layer that slows the reaction. The "inches thick" growth implies a Latent Catalytic Mechanism that kept the reaction active for years, violating standard passivation kinetics.

- Classification: Athermal ionic dissociation / passivation-failure phenotype, with galvanic acceleration carried as a secondary accelerator where local electrolytes/dissimilar-metal couples are documented.

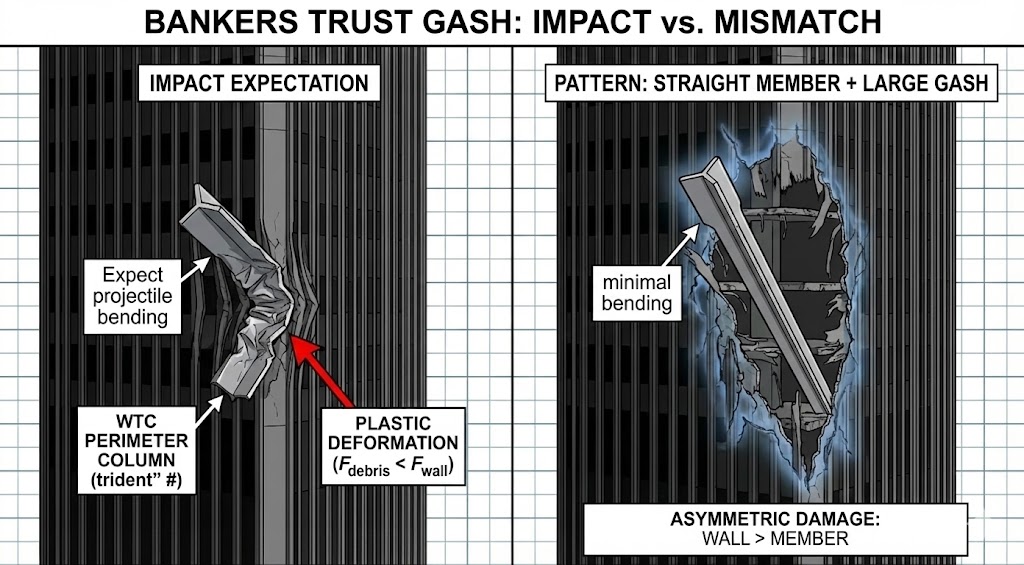

EVIDENCE FILE C: Anomalous Vector Damage (Bankers Trust)¶

- Visual Data: The Bankers Trust building exhibits a large, circular gash. The impacting debris (Prefabricated Perimeter Column Assembly) hangs suspended in the gash. Crucially, the debris is Geometrically Linear (Sharp, Unbent, Pristine), showing zero significant buckling despite the massive energy required to shear the target building's façade, and is significantly smaller than the hole it allegedly created.

- The Standard Model Defense: "Falling debris mechanically impacted and tore the facade."

- Boundary Condition Violation:

- Energy Dissipation Paradox: In a high-velocity collision ($\(KE = \frac{1}{2}mv^2\)$), energy is dissipated via Plastic Deformation (Heat and Bending) of both bodies.

- Yield Strength Constraint: A steel column impacting a steel/concrete façade with enough force to shear a 3-story hole must exceed its own Yield Strength ($\(F > F_{yield}\)$). It should buckle, twist, or crush (Plastic Hinge formation).

- Observation: The Target (Building) failed catastrophically; the Projectile (Column) exhibited Elastic/Rigid Behavior (remained straight).

- Implication: In high-energy impacts, significant deformation can localize unevenly, but a scenario where the target exhibits catastrophic removal while the impacting assembly remains notably straight motivates a mismatch/decoupling hypothesis (e.g., impact geometry/support conditions, pre-damage/cutting, material variability, or localized weakening of the target). Within this dossier, “impedance mismatch / field-mediated softening” is carried as the leading coupling hypothesis once mechanical alternatives are bounded by structural/forensic reconstruction.

- Classification: Field-Mediated Erosion / Impedance Mismatch.

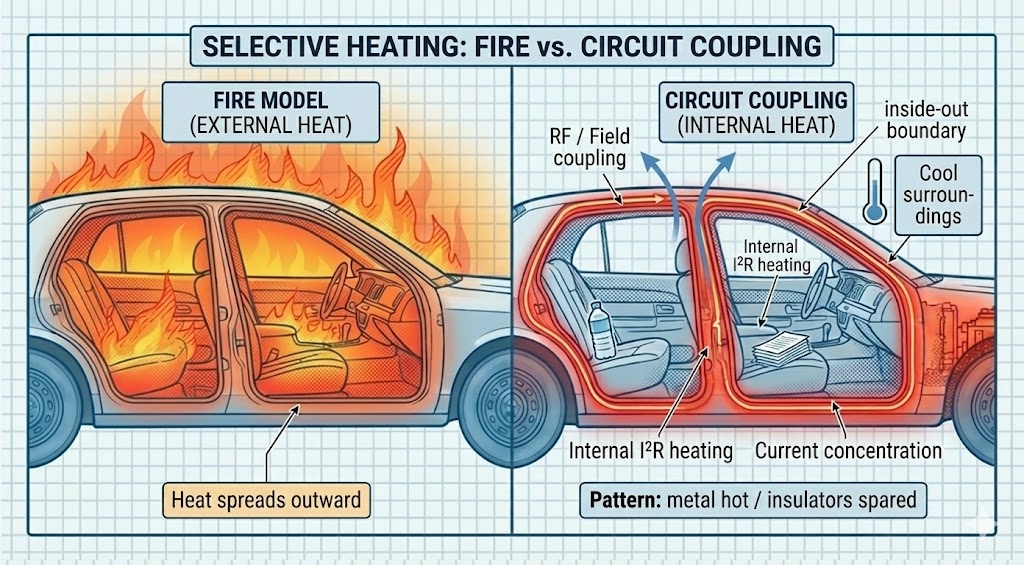

EVIDENCE FILE D: Selective Impedance Heating (Vehicles)¶

- Visual Data: Police Car #2723 shows a sharp boundary: the interior door panel is rusted/consumed, while the exterior door panel is "waxed" and pristine. The Pepsi Truck exhibits a rust pattern resembling a "Point-of-Impact Splash," with windshield glass gone but underlying paint discolored.

- The Standard Model Defense: "Fire" or "Weathering."

- Boundary Condition Violation:

- The "Inside-Out" Anomaly: Weathering attacks the Exterior first. Fire attacks Combustibles first.

- Observation: The Interior metal panel is rusted (destroyed), while the Exterior wax/paint is intact.

- Mechanism: This violates Convective Heat Transfer ($\(q=hA\Delta T\)$) and Atmospheric Diffusion. It requires internal heating via conductive-loop coupling (CLC) to the frame’s conductive loop (downstream $\(P=I2RP=I^2RP=I2R\)$ ), driving oxidation from the inside out.

- Classification: Interferometric Side-Lobe Radiation / conductive-loop coupling ($\(CLC → P=I2RP=I^2RP=I2R\)$ ; SIH phenotype where claimed).

4. CORROBORATING BIO-TELEMETRY & SENSORY DATA¶

All descriptive inputs for this record are morphological characterizations of static physical evidence and have been fully integrated into Section 3: Data Curation. No independent biological transducer telemetry (witness accounts) is available for this specific vector.

5. MECHANISMS OF NON-THERMAL FAILURE (Summary)¶

- Phenomenon: Laminar Exfoliation & Curling $\(\rightarrow\)$ Mechanism: Interferometric Molecular Dissociation (IMD). Field-localized coupling initiates bond scission and section loss while adjacent regions remain weakly coupled.

- Phenomenon: Macroscopic Void Formation $\(\rightarrow\)$ Mechanism: Field-Driven Atomic Transport (electro-migration) / vacancy clustering occurring within an IMD/ECR exposure regime.

- Phenomenon: Rapid "Fuming" / Hyper-Accelerated Oxidation $\(\rightarrow\)$ Mechanism: Athermal Ionic Dissociation / Field-Activated Oxidation (passivation failure), with secondary galvanic acceleration where applicable.

- Phenomenon: Selective Vehicle Impedance Heating $\(\rightarrow\)$ Mechanism: Selective Vehicle Impedance Heating → Mechanism: Interferometric Side-Lobe Radiation / CLC coupling. Conductive loops couple, generating internal heat ($\(P=I2RP=I^2RP=I2R\)$).

- Phenomenon: Pristine prefabricated perimeter column assembly vs. gashed facade $\(\rightarrow\)$ Mechanism: Impedance mismatch / field-mediated softening (momentary reduction of lattice binding energy within node geometry).

6. MICROSCOPY PROTOCOL¶

Objective: Distinguish Chemical Corrosion from Lattice Dissociation.

TEST A: Cross-Sectional Porosity (The "Kirkendall" Test)¶

- Sample: A thinned "Tissue Beam" fragment.

- Standard Prediction (Corrosion/Erosion):

- Morphology: Surface Pitting. The damage moves from the Outside -> In. The core metal remains solid.

- SCIE Prediction (Dissociation):

- Morphology: Internal Voiding. We look for deep internal voiding consistent with vacancy clustering / Kirkendall-type void formation versus purely surface-initiated pitting. If present, this supports an atomic-transport/voiding pathway operating within an IMD/ECR exposure regime rather than simple external etching alone.

TEST B: Oxide Stoichiometry (The "Phase" Test)¶

- Sample: The rust layer on the beam.

- Standard Prediction (Atmospheric):

- Chemistry: Hydrated Iron Oxide ($\(Fe_2O_3 \cdot H_2O\)$). Standard slow rust (Goethite/Lepidocrocite).

- Standard Prediction (High-T Fire):

- Chemistry: Thick Scale. Delaminating layers of Wüstite/Magnetite with clear thermal stratification.

- SCIE Prediction (Anomalous):

- Chemistry: High-T Phases on "Cold" Beams. Finding FeO (wüstite)—a phase associated with high-temperature or specific oxygen-potential conditions—would indicate a nontrivial thermal/chemical environment at least locally. If high-temperature oxide phases are present without corresponding bulk heat-treatment signatures (grain growth/phase changes consistent with sustained soak), that supports a localized/brief or strongly non-uniform energy deposition history rather than uniform long-duration heating.

7. SYNTHESIS: The SCIE Classification Protocol¶

Thermodynamic Gap: The energy required to dissociate steel lattice bonds ( $\(E_{dissoc}\)$) and accelerate oxidation by orders of magnitude exceeds the gravitational potential ( $\(U_g\)$) and available chemical energy (hydrocarbons) in the localized zones. $\(E_{total} \gg U_g + E_{chem}\)$.

Circuit Gap: The "Model B" (Interferometric Coupling) hypothesis explains the selectivity (conductors vs. insulators), the morphology (thinning/curling from skin effects), and the kinetics (rapid oxidation from ionization) which the Standard Model (gravity/fire) fails to resolve.

The Classification:

- Rule A (Attributes): The event demonstrates Selective Coupling (metal affected, paper/paint spared), Geometric Flux Constraint (damage localized to specific beams/cars), and Systemic Circuit Integration (grounded steel members acting as electrodes).

- Rule B (Justification): Within the mechanism classes evaluated in this dossier, the data set is scored as consistent with a Spatially-Constrained Interferometric Event (SCIE)-class environment. The cited phenotypes (localized section loss, accelerated oxidation/aging behavior where documented, and material-selective alteration signatures) motivate a structured field-coupling hypothesis — the environment was subjected to a high-intensity, structured electromagnetic field.